Zinc–bromine battery

A zinc-bromine battery is a rechargeable battery system that uses the reaction between zinc metal and bromine to produce electric current, with an electrolyte composed of an aqueous solution of zinc bromide. It is being developed as an alternative to lithium-ion batteries for stationary power applications from domestic through to grid-scale. The water-based electrolyte makes the battery system less prone to overheating and fire compared with lithium-ion battery systems.

| Specific energy | 60-85 W·h/kg |

|---|---|

| Energy density | 15–65 W·h/L (56–230 kJ/L)[1] |

| Charge/discharge efficiency | 75.9%[2] |

| Energy/consumer-price | US$400/kW·h (US$0.11/kJ) |

| Cycle durability | >2,000 cycles |

| Nominal cell voltage | 1.8 V |

Overview

Zinc-bromine batteries can be split into two groups - flow batteries and non-flow batteries.

Redflow (Australia) and Primus Power (USA) are active in commercialising zinc-bromine flow batteries whilst Gelion (Australia) and EOS Energy Enterprises (USA) are developing and commercialising their non-flow zinc-bromine batteries.

Common features of zinc-bromine battery chemistry

Both flow and non-flow zinc-bromine batteries share many advantages over incumbent lithium-ion storage systems.

- 100% depth of discharge capability on a daily basis.[3]

- Little capacity degradation enabling 5000+ cycles

- Low fire risk as electrolyte is non-flammable

- No need for cooling systems

- Use of low cost and readily available battery materials

- Easy of end-of-life recycling using existing processes

They also share some disadvantages

- Lower energy density than li-ion batteries

- Lower Round Trip Efficiency than li-ion (although this is partially offset by the energy drawn from li-ion installations to run cooling systems).

- The need to be fully discharged every few days to prevent zinc dendrites that can puncture the separator.[3]

- Lower charge and discharge rates than Li-ion

These features make zinc-bromine batteries unsuitable for mobile applications (that require high charge discharge rates and low weight) but highly suitable for stationary energy storage applications such daily cycling to support solar power generation, off-grid systems and load shifting.

Zinc-bromine flow battery

The zinc–bromine flow battery is a type of hybrid flow battery. A solution of zinc bromide is stored in two tanks. When the battery is charged or discharged, the solutions (electrolytes) are pumped through a reactor stack and back into the tanks. One tank is used to store the electrolyte for the positive electrode reactions, and the other for the negative. Zinc–bromine flow batteries from different manufacturers have energy densities ranging from 60 to 85 W·h/kg.[1]

The predominantly aqueous electrolyte is composed of zinc bromide salt dissolved in water. During charge, metallic zinc is plated from the electrolyte solution onto the negative (carbon felt in older designs, titanium mesh in modern) electrode surfaces in the cell stacks. Bromide is converted to bromine at the positive electrode surface and is stored in a safe, chemically complexed organic phase in the electrolyte tank. Older ZBRFB cells used polymer membranes (microporous polymers, Nafion etc.) More recent designs do not use a membrane at all.[4] The battery stack is typically made of carbon-filled plastic bipolar plates (e.g. 60 cells), and it is enclosed into a high-density polyethylene (HDPE) container. The zinc–bromine battery can be regarded as an electroplating machine. During charging, zinc is electroplated onto conductive electrodes, while at the same time bromine is formed. On discharge, the reverse process occurs: the metallic zinc plated on the negative electrodes dissolves in the electrolyte and is available to be plated again at the next charge cycle. It can be left fully discharged indefinitely without damage. There is no self-discharge in a fully charged state, when the stack is kept dry.

Features of zinc-bromine flow batteries

In addition to the general advantages of the chemistry, zinc-bromine flow batteries have advantages of:

- Scalable to large storage capacity through larger tanks and stacks, eg. Primus Power produces a 125kWhr unit and Redflow a 10kWhr unit.

- Individual parts can be serviced or replaced for example the pump, tanks or electrolyte.

Zinc-bromine flow batteries also have some specific disadvantages of their design, these include:

- The need every 1–4 cycles to short the terminals across a low-impedance shunt while running the electrolyte pump, to fully remove zinc from battery plates.[3]

- Low areal power (<0.2 W/cm2) during both charge and discharge, which translates into a high cost of power.[5][6][7]

- Low Round Trip Efficiency with Redflow claiming 80% and Primus Power just 70%.[8] This is significantly lower than li-ion batteries that are typically 90% or more.

- Complex construction with moving parts

Zinc–bromine flow battery developers include:

- Primus Power – Hayward, California, USA. A privately held US company.

- RedFlow Limited – Brisbane, Australia. A publicly listed company on the ASX.

- Smart Energy – Shanghai, China.

- EnSync (Formerly ZBB)[9] – Menomonee Falls, Wisconsin, USA. However they have since become insolvent and are no longer operating. See

- ZBEST Power – Beijing, China.

Zinc–bromine non-flow batteries

Zinc-bromine non-flow battery providers include:

- Gelion Technologies - Sydney, NSW Australia

- EOS Energy Enterprises - Edison, New Jersey USA

Gelion gel zinc-bromine battery

A development, by Thomas Maschmeyer from the University of Sydney, replaces the liquid with a gel. Gel is neither a liquid nor a solid, but has the advantages of both. Ions can move quicker, decreasing charging time. It is also more efficient, longer-lasting, and cheaper than lithium, and the gel is fire-retardant.[10] As of April 2016, Gelion, launched as a spin-off company of Sydney University, to develop the battery for commercial use. The company was boosted by an $11 million investment from UK renewables group Armstrong Energy.[11] Gelion raised further capital with an IPO and listed on the AIM London Stock Exchange 30 November 2021.

Gelion plans to use the funds to commercialise a 1.2Kwhr monoblock battery for use in commercial and grid scale applications.[12] Gelion claim their monoblocks will have many advantages compared to zinc-bromine flow batteries, these include:[12]

- Significantly higher energy density of (120Whr/kg)

- Significantly higher Round Trip Efficiency (RTE >87%)

- Cheaper to produce with no moving parts

- Manufacturing easily scalable to gigawatt factory capacity by utilising existing lead-acid battery factories

As of February 2022, Gelion announced that it had signed an agreement with Acciona Energy to trial its Endure gel zinc-bromine batteries for potential grid scale applications. The trial is due to commence July 2022 and run for 6–12 months.[13]

EOS Energy Enterprise zinc-hybrid cathode battery

As of November 2021, EOS are commercialising their Znyth® “zinc hybrid cathode” battery.[14] This is a non-flow battery design that also uses zinc-bromine chemistry.

EOS claim a RTE of 80%; however, few details are currently publicly available regarding the design or performance of their battery.

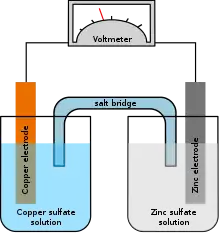

Electrochemistry

Both flow and non-flow zinc-bromine batteries share the same electrochemistry.

At the negative electrode zinc is the electroactive species. Zinc has long been used as the negative electrode of primary cells. It is a widely available, relatively inexpensive metal, which is electropositive, with a standard reduction potential E° = −0.76 V vs SHE. However, it is rather stable in contact with neutral and alkaline aqueous solutions. For this reason, it is used today in zinc–carbon and alkaline primaries.

In zinc–bromine batteries the negative electrode reaction is the reversible dissolution/plating of zinc:

At the positive electrode bromine is reversibly reduced to bromide (with a standard reduction potential of +1.087 V vs SHE):

The overall cell reaction is therefore

The measured potential difference is around 1.67 V per cell (slightly less than that predicted from the standard reduction potentials).

The two electrode chambers of each cell in both flow and non-flow designs are divided by a membrane (typically a microporous or ion-exchange variety). This helps to prevent bromine from reaching the positive electrode, where it would react with the zinc, causing the battery to self-discharge. To further reduce self-discharge and to reduce the vapor pressure of bromine, complexing agents are added to the positive electrolyte. These react reversibly with the bromine to form an oily red liquid and reduce the Br

2 concentration in the electrolyte.

Applications

Remote telecom sites

Significant diesel generator fuel savings are possible at remote telecom sites operating under conditions of low electrical load and large installed generation using multiple systems in parallel to maximize the benefits and minimize the drawbacks of the technology.[15]

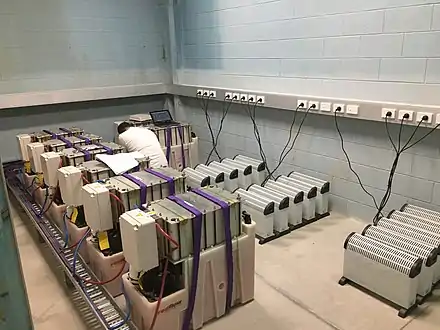

List of major applications and installations of zinc-bromine batteries

- In December 2021, Redflow completed a 2MWhr installation for Aneargia to support a 2.0MW biogas-fueled cogeneration unit, and a microgrid control system in California, USA.[16][17]

- As of November 2021 EOS Energy Enterprises has secured a 300MWhr order from Pine Gate Renewables with installation planned for 2022.[18]

- As of February 2022, Gelion announced that it had signed an agreement with Acciona Energy to trial Endure batteries for potential grid scale applications. The trial is due to commence July 2022 and run for 6–12 months.[13]

References

- Khor, A.; Leung, P.; Mohamed, M.R.; Flox, C.; Xu, Q.; An, L.; Wills, R.G.A.; Morante, J.R.; Shah, A.A. (June 2018). "Review of zinc-based hybrid flow batteries: From fundamentals to applications". Materials Today Energy. 8: 80–108. doi:10.1016/j.mtener.2017.12.012. hdl:10397/77992. S2CID 117522227.

- "Performance Testing of Zinc-Bromine Flow Batteries for Remote Telecom Sites" (PDF). Sandia National Laboratories. 2013. p. 6. Retrieved 2015-04-01.

- Rose & Ferreira, p. 4.

- "US20200036046 MEMBRANE-FREE NON-FLOWING SINGLE CELL ZINC BROMINE BATTERY WITH BROMINE-TRAPPING COMPOSITE CARBON FOAM ELECTRODE". patentscope.wipo.int.

- G. P. Corey, An Assessment of the State of the Zinc-Bromine Battery Development Effort. RedFlowLimited Brisbane, Queensland, Australia, 2011.

- Nakatsuji-Mather, M.; Saha, T. K. (2012). "Zinc-bromine flow batteries in residential electricity supply: Two case studies". 2012 IEEE Power and Energy Society General Meeting. pp. 1–8. doi:10.1109/PESGM.2012.6344777. ISBN 978-1-4673-2729-9. S2CID 22810353.

- Suresh, S.; Kesavan, T.; Munaiah, Y.; Arulraj, I.; Dheenadayalan, S.; Ragupathy, P. (2014). "Zinc–bromine hybrid flow battery: effect of zinc utilization and performance characteristics". RSC Advances. 4 (71): 37947. Bibcode:2014RSCAd...437947S. doi:10.1039/C4RA05946H. ISSN 2046-2069.

- "Primus Power". primuspower.com. Retrieved 2022-02-08.

- "ZBB Energy changes name to EnSync" (Press release).

- "Catalyst/BATTERY POWERED HOMES". Australian Broadcasting Corporation. 2 February 2016. Retrieved 15 January 2017.

- "Australian gel-based battery technology attracts major UK finance". 13 April 2016. Retrieved 15 January 2017.

- "Presentations | Gelion - Inspired Energy". Retrieved 2022-02-08.

- Vorrath, Sophie (2022-02-02). "Gelion to trial its zinc bromide batteries with Spanish solar farm". RenewEconomy. Retrieved 2022-02-08.

- "Product". Retrieved 2022-04-13.

- Rose & Ferreira, p. 10.

- "Redflow signs its largest global battery sale with Anaergia to supply energy storage in California". Anaergia. 2021-03-13. Retrieved 2022-02-08.

- "Redflow completes 2 MWh installation in California – Redflow". Retrieved 2022-02-08.

- "Eos Energy secures order for 300 MWh of battery storage systems". Renewablesnow.com. Retrieved 2022-02-08.

Further reading

- Bromine Complexation in Zinc–Bromine Circulating Batteries D. J. Eustace, J. Electrochem. Soc. 127(3), 528–32 (1980)

- Handbook of batteries, 3rd edition. D. Linden, T. B. Reddy. 39.1–39.8 (2002)

- Rose, David M.; Ferreira, Summer R. "Performance Testing of Zinc-Bromine Flow Batteries for Remote Telecom Sites" (PDF). Sandia National Laboratory. Update

- RedFlow.

External links

- ZnBr Batteries at the Electricity Storage Association