Lignocellulosic biomass

Lignocellulose refers to plant dry matter (biomass), so called lignocellulosic biomass. It is the most abundantly available raw material on the Earth for the production of biofuels. It is composed of two kinds of carbohydrate polymers, cellulose and hemicellulose, and an aromatic-rich polymer called lignin. Each has distinct chemical behavior. Being a composite of three very different components makes the processing of lignocellulose challenging. The highly evolved resistance to degradation or even separation is referred to as recalcitrance. Overcoming this recalcitrance to produce useful, high value products requires a combination of heat, chemicals, enzymes, and microorganisms.[1][2][3][4] These carbohydrate-containing polymers contain different sugar monomers (six and five carbon sugars) and they are covalently bound to lignin. Lignocellulosic biomass can be broadly classified into virgin biomass, waste biomass, and energy crops. Virgin biomass includes all naturally occurring terrestrial plants such as trees, bushes and grass. Waste biomass is produced as a low value byproduct of various industrial sectors such as agriculture (corn stover, sugarcane bagasse, straw etc.) and forestry (saw mill and paper mill discards). Energy crops are crops with high yield of lignocellulosic biomass produced to serve as a raw material for production of second generation biofuel; examples include switchgrass (Panicum virgatum) and Elephant grass.

Chemical composition

Lignocellulose consists of three components, each with properties that pose challenges to commercial applications.[6]

- lignin is a heterogeneous, highly crosslinked polymer akin to phenol-formaldehyde resins. It is derived from 3-4 monomers, the ratio of which varies from species to species. The crosslinking is extensive. Being rich in aromatics, lignin is hydrophobic and relatively rigid. Lignin confers structural integrity to plants. Lignin is so heterogeneous and so recalcitrant that its value is almost exclusively measured as a fuel.

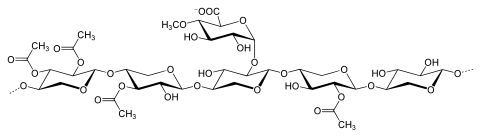

- hemicellulose is composed of branched polysaccarides. A particular problem is that hemicellolose is covalently linked to ligin, usually through ferulic acid component of the lignin.[7]

- cellulose is a homopolymer of glucose. It is very poorly soluble in most solvents. The strands of cellulose are integrated into, but not covalently attached to the lignin-hemicellulose component.

Dedicated energy crops

Many crops are of interest for their ability to provide high yields of biomass . Some can be harvested multiple times each year. These include poplar trees and Miscanthus giganteus. The premier energy crop is sugarcane, which is a source of the readily fermentable sucrose and the lignocellulosic by-product bagasse.

Application

Pulp and paper industry

Lignocellulosic biomass is the feedstock for the pulp and paper industry. This industry, which energy-intensive, involves the separation of the lignin and cellulosic fractions of the biomass. The lignin component is generally burned as fuel for the overall process.

Biofuels

Lignocellulosic biomass, in the form of wood fuel, has a long history as a source of energy. Since the middle of the 20th century, the interest of biomass as a precursor to liquid fuels has increased. To be specific, the fermentation of lignocellulosic biomass to ethanol[8] is an attractive route to fuels that supplements the fossil fuels. Biomass can be a carbon neutral source of energy in the long run. However depending on the source of biomass, it will not be carbon neutral in the short term. For instance if the biomass is derived from trees, the time period to regrow the tree (on the order of decades) will see a net increase in carbon dioxide in the earth’s atmosphere upon the combustion of lignocellulosic ethanol. However, if woody material from annual crop residue is used, the fuel could be considered carbon-neutral. Aside from ethanol, many other lignocellulose-derived fuels are of potential interest, including butanol, dimethylfuran, and gamma-Valerolactone.[9]

One barrier to the production of ethanol from biomass is that the sugars necessary for fermentation are trapped inside the lignocellulose. Lignocellulose has evolved to resist degradation and to confer hydrolytic stability and structural robustness to the cell walls of the plants. This robustness or "recalcitrance" is attributable to the crosslinking between the polysaccharides (cellulose and hemicellulose) and the lignin via ester and ether linkages.[10] Ester linkages arise between oxidized sugars, the uronic acids, and the phenols and phenylpropanols functionalities of the lignin. To extract the fermentable sugars, one must first disconnect the celluloses from the lignin, and then use acid or enzymatic methods to hydrolyze the newly freed celluloses to break them down into simple monosaccharides. Another challenge to biomass fermentation is the high percentage of pentoses in the hemicellulose, such as xylose, or wood sugar. Unlike hexoses such as glucose, pentoses are difficult to ferment. The problems presented by the lignin and hemicellulose fractions are the foci of much contemporary research.

A large sector of research into the exploitation of lignocellulosic biomass as a feedstock for bio-ethanol focuses particularly on the fungus Trichoderma reesei, known for its cellulolytic abilities. Multiple avenues are being explored including the design of an optimised cocktail of cellulases and hemicellulases isolated from T. reesei, as well as genetic-engineering-based strain improvement to allow the fungus to simply be placed in the presence of lignocellulosic biomass and break down the matter into D-glucose monomers.[11] Strain improvement methods have led to strains capable of producing significantly more cellulases than the original QM6a isolate; certain industrial strains are known to produce up to 100g of cellulase per litre of fungus, thus allowing for maximal extraction of sugars from lignocellulosic biomass. These sugars can then be fermented, leading to bio-ethanol.

Research

Some chemicals could be obtained from lignocellulosic biomass. Almost all are derived from the sugars obtained by hydolysis of the cellulose component.[12]

Lignocellulosic biomasses has been considered in the production of biocomposites materials such as particle panels, wood-plastic composites, and cement/geopolymer wood composites. Even though the production of biocomposites material rely mostly on wood resources, in less forest-covered countries or in countries where wood resources are already being overused, it is possible to utilize alternative sources of biomass such as invasive plants, agricultural and sawmills residues for the creation of new "green" composites.

Biocomposites produced with lignocellulosic biomasses as alternative to conventional materials, are attracting the attention because are renewable and cheaper but also because they fit perfectly into the policy of the "cascade utilization" of the resources.

References

- Y. Sun, J. Cheng (2002). "Hydrolysis of Lignocellulosic Materials for Ethanol Production: a Review". Bioresour. Technol. 83: 1-11. doi:10.1016/S0960-8524(01)00212-7.

- E. Palmqvist; B. Hahn-Hagerdal (2000). "Fermentation of Lignocellulosic Hydrolysates. II: inhibitors and Mechanisms of Inhibition". Bioresour. Technol. 74: 25-33. doi:10.1016/S0960-8524(99)00161-3.

- P. Alvira; E. Tomas-Pejo; M. Ballesteros; M. J. Negro (2010). "Pretreatment Technologies for an Efficient Bioethanol Production Process Based on Enzymatic Hydrolysis: A Review". Bioresour. Technol. 101: 4851-4861. doi:10.1016/j.biortech.200911.093.

- D. M. Alonso; J. Q. Bond; J. A. Dumesic (2010). "Catalytic Conversion of Biomass to Biofuels". Green Chem. 12: 1493-1513. doi:10.1039/c004654j.

- Horst H. Nimz, Uwe Schmitt, Eckart Schwab, Otto Wittmann, Franz Wolf "Wood" in Ullmann's Encyclopedia of Industrial Chemistry 2005, Wiley-VCH, Weinheim. doi:10.1002/14356007.a28_305

- Christopher M. Fellows, Trevor C. Brown, William O.S. Doherty (2011). "Lignocellulosics as a Renewable Feedstock for Chemical Industry: Chemicals from Lignin". In Rashmi Sanghi, Vandana Singh (ed.). Green Chemistry for Environmental Remediation. pp. 561–610. doi:10.1002/9781118287705.ch18. ISBN 9781118287705.

{{cite book}}: CS1 maint: multiple names: authors list (link) - De Oliveira, Dyoni Matias; Finger-Teixeira, Aline; Rodrigues Mota, Thatiane; Salvador, Victor Hugo; Moreira-Vilar, Flávia Carolina; Correa Molinari, Hugo Bruno; Craig Mitchell, Rowan Andrew; Marchiosi, Rogério; Ferrarese-Filho, Osvaldo; Dantas Dos Santos, Wanderley (2015). "Ferulic acid: A Key Component in Grass Lignocellulose Recalcitrance to Hydrolysis". Plant Biotechnology Journal. 13 (9): 1224–1232. doi:10.1111/pbi.12292. PMID 25417596.

- Carroll, Andrew; Somerville, Chris (June 2009). "Cellulosic Biofuels". Annual Review of Plant Biology. 60 (1): 165–182. doi:10.1146/annurev.arplant.043008.092125.

- Barbara A. Tokay "Biomass Chemicals" in Ullmann's Encyclopedia of Industrial Chemistry 2002, Wiley-VCH, Weinheim. doi:10.1002/14356007.a04_099

- U.S. Department of Energy Office of Science (June 2006). "Breaking the Biological Barriers to Cellulosic Ethanol: A Joint Research Agenda. Report from the December 2005 Workshop" (PDF). Archived from the original (PDF) on 2017-02-07. Retrieved 2008-01-19.

- Monot, Frederic; Margeot, Antoine. "Biofuels turn to fungus - Interview with Frédéric Monot and Antoine Margeot, Applied Chemistry and Physical Chemistry Division at IFPEN". IFP Energies nouvelles. Archived from the original on January 27, 2018. Retrieved July 17, 2015.

- "Top Value Added Chemicals from Biomass Volume I—Results of Screening for Potential Candidates from Sugars and Synthesis Gas" (PDF).